Aluminum Gravity Casting for engine inlet outlet pipe

Short Description: MOQ: 500kg Material: Aluminum alloy Lead Time: 25 days for mold. Production depends on quantity Tolerance: High Precision Machining Offered. JPR Model is a professional company designing and producing rapid prototyping, cnc machining parts, sheet metal parts and aluminum casting parts. With international advanced equipment and experienced technical team, our company can meet or exceed your expectation in precision, appearance, performance and service life. With the goal of helping our custome...

Product Detail:

MOQ: 500kg

Material: Aluminum alloy

Lead Time: 25 days for mold. Production depends on quantity

Tolerance: High Precision Machining Offered.

JPR Model is a professional company designing and producing rapid prototyping, cnc machining parts, sheet metal parts and aluminum casting parts. With international advanced equipment and experienced technical team, our company can meet or exceed your expectation in precision, appearance, performance and service life. With the goal of helping our customer to save their development time and cost, we will provide one-stop service to make sure you are satisfied with all the details. We provide micro machining and OEM ODM cnc machining service.

Aluminum gravity casting has a low melting point and good casting performance. It is widely used in many fields such as automobiles, motorcycles, motors, telecommunications, and hardware tools. Aluminum gravity casting can be divided into sand casting and metal casting according to the material of the casting. Our factory is very comfortable with these two casting processes, and designs and manufactures these two types of casting molds.

· It can serve for parts with undercut by sand-core to meet the feature needs. The metal is introduced into the mold by the force of gravity so the constraint is the wall thickness, the minimum of which is 3.5mm. The mold is made of steel and sand (with resin core).

· Gravity die casting is a natural partner to sand casting, and allows us to offer the customer the most cost effective route for casting manufacture

Kinds of industries JPR Model serves including mechanical, auto & motorcycle, lighting, electronic, public facilities, etc. Aluminum gravity casting auto parts series is one of the traditional products of JPR Model, like engine inlet outlet pipe. We provides one-stop OEM service, from tooling, die casting, machining, surface treatment, to storage and shipment. It also provides other related products and service according to customers’ requirements.JPR Model aims to be a first-class international enterprise, welcome customers from all over the world!

|

Material |

ADC12; A380; A319; Alsi9cu3; etc |

|

Weight |

0.015-8kg (0.033-18lb) |

|

Production Process |

1 Sign Drawing |

|

Drawing |

Provide by customer, or design according as the sample |

|

Drwing format |

Pro/E, AutoCAD, SOLIDWORK, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. |

|

Service |

OEM/ODM |

Related Products

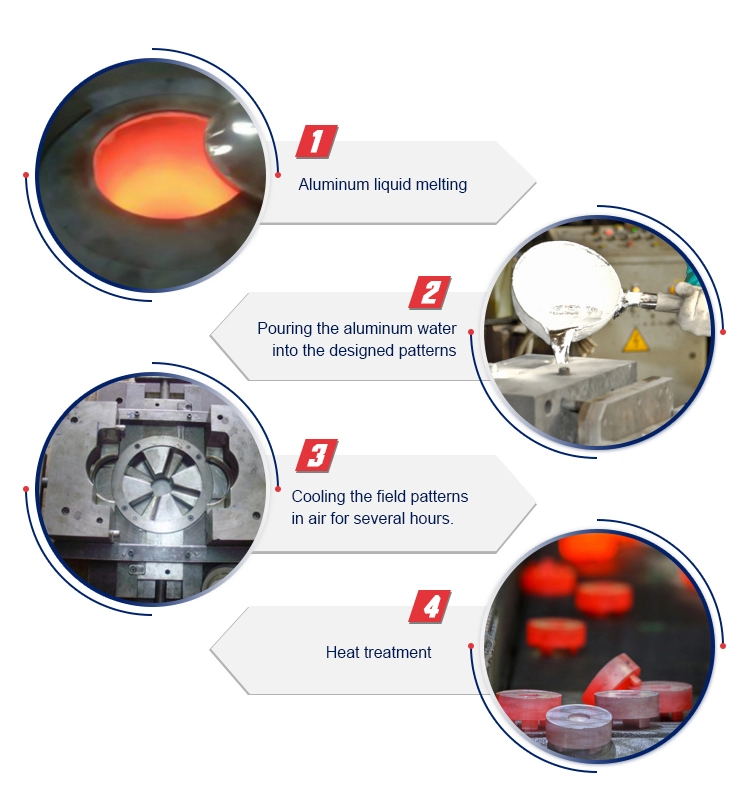

Product Process